Injector cleaning and protection

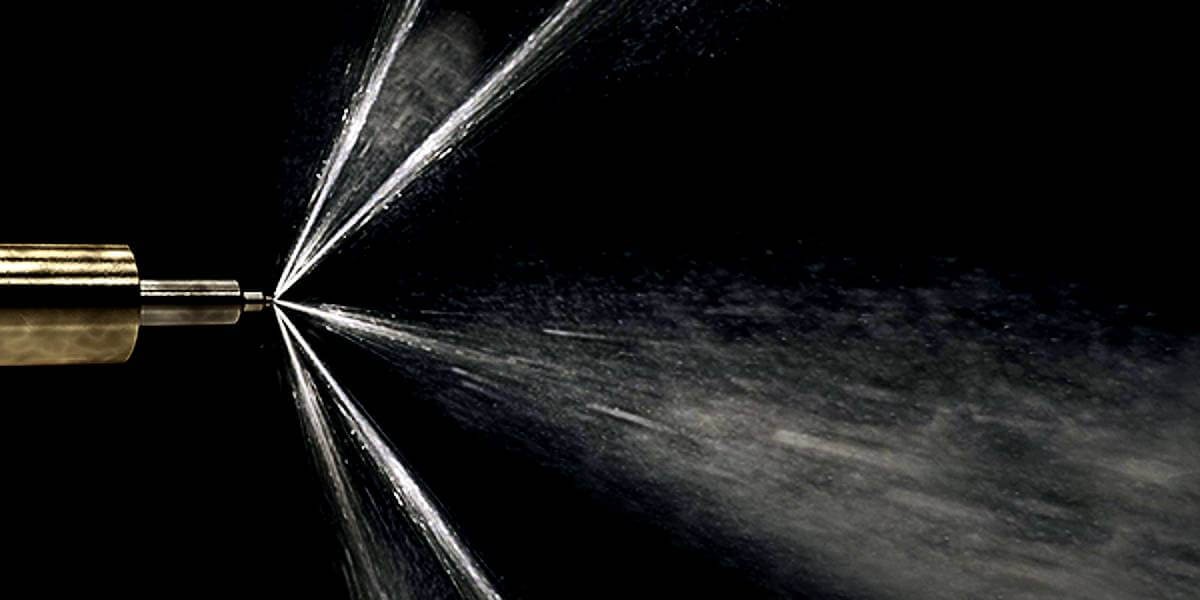

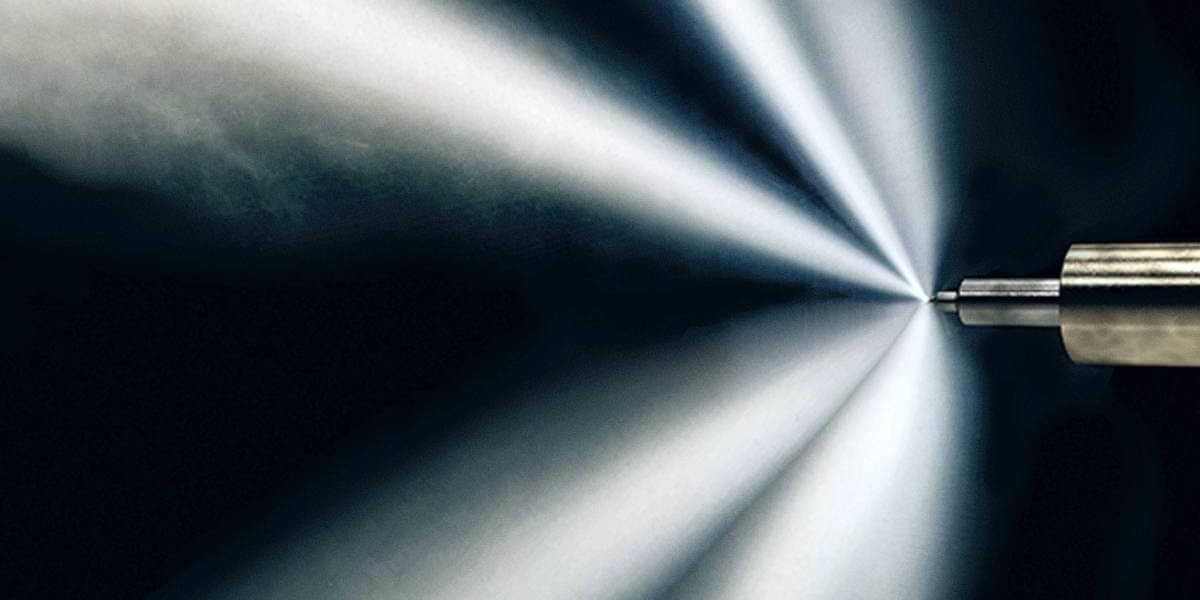

Injectors are one of the essential components of an internal combustion engine. In order for them to work, optimal maintenance and care is necessary: This includes regular cleaning of the injectors. New cleaning technologies ensure the value of the fuel system and improved driving performance. This includes, for example, protecting the injector nozzles, which are now only the diameter of a hair, from coking and deposits. Our solutions for fuel system cleaning (e.g. injector protection, fuel protection, LPG / CNG) help to make the affected vehicles ready for use again in a short time and with low material costs.

What are injectors and what is their function?

Injectors are part of the fuel injection system and they play a key role in the operation of a vehicle. It is their job to supply the cylinders of an engine with the right dose of fuel at a precisely defined point in time. The injection system is an essential part of an engine, because if it fails, the vehicle won't start anymore. The injection system is particularly impaired by deposits of the bio-components of the fuel on the injector needle.

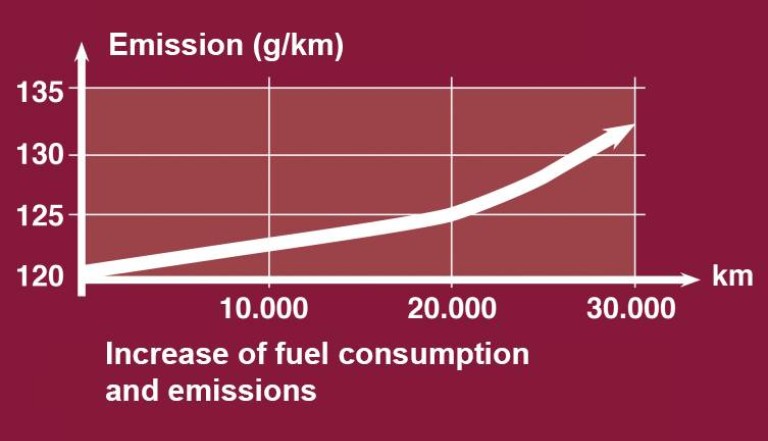

What happens if the injectors are not cleaned?

Unnecessary increase in consumption and emissions.

Diesel, Super, E10, B7... The fuel selection at the petrol station is developing more and more into a highly complex science behind the scenes. Internationally different legislations, the technically very demanding engine technology and the increasingly ambitious emissions standards ensure that the harmony between fuel and vehicle is increasingly dwindling.

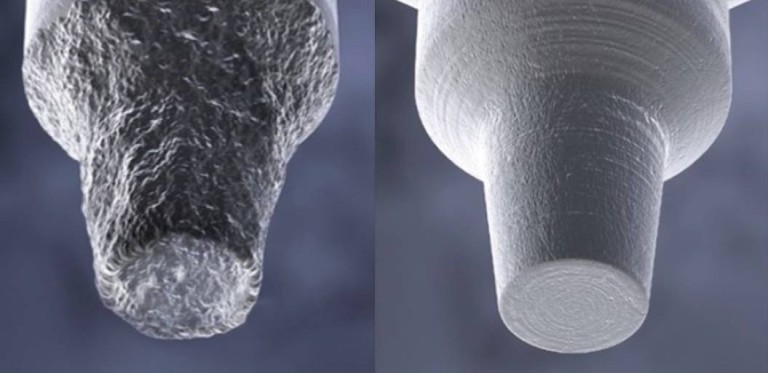

The result is chemical processes in the fuel system that can lead to soiling, deposits, coking and varnish on the injectors. This means that the injector nozzles can no longer bring enough fuel into the combustion chamber.

Left picture: dirty injection nozzle; right picture: clean injection nozzle

The negative consequences of contaminated injectors

- Higher pollutant emissions,

- poor throttle response,

- Performance degradation,

- increased consumption,

- uneven engine running,

- premature wear of all components,

- which in total results in an expensive replacement of parts.

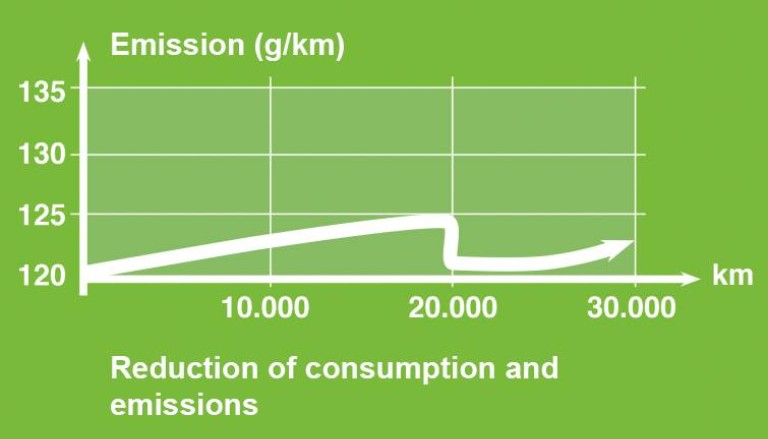

Reduction of emissions and consumption.

Protection and care of the fuel system: cleaning instead of replacing

Our solutions for fuel system cleaning reliably remove deposits and impurities in the engine and on injectors. Preventive products or problem solutions are available as required. Innovative chemistry is combined with specific tool technology. The positive effects of a cleaned fuel system and / or cleaned injectors are:

- Reduced emissions,

- lower fuel consumption,

- fewer repairs and workshop visits,

- significant cost savings and

- higher customer satisfaction.

Discover the fuel products of our microflex® engine efficiency series in the video

A comparison of a dirty and a cleaned injector

When and how often should injectors be cleaned?

- The injectors should be cleaned once a year with our injector direct cleaner products for diesel or petrol.

- Our injector direct protection should be added to the next tank filling - and then about every 5000 kilometers.

- In addition, if the cleaning effect is insufficient, our injector intensive cleaner can be added.