For plastic injection molding systems

For plastic injection molding systems

Plastic injection molding

The plastics industry produces for very heterogeneous markets, with different target groups and requirements. The choice of lubricants must also take these into account. Plastic parts for the technology sector require high precision, while those for the food sector or toys must be harmless. This applies to small and large plastic parts, for short runs and mass production.

Challenges in plastic injection molding production

Flawless quality and maximum production efficiency are key success factors in the production process of the plastic injection molding industry.

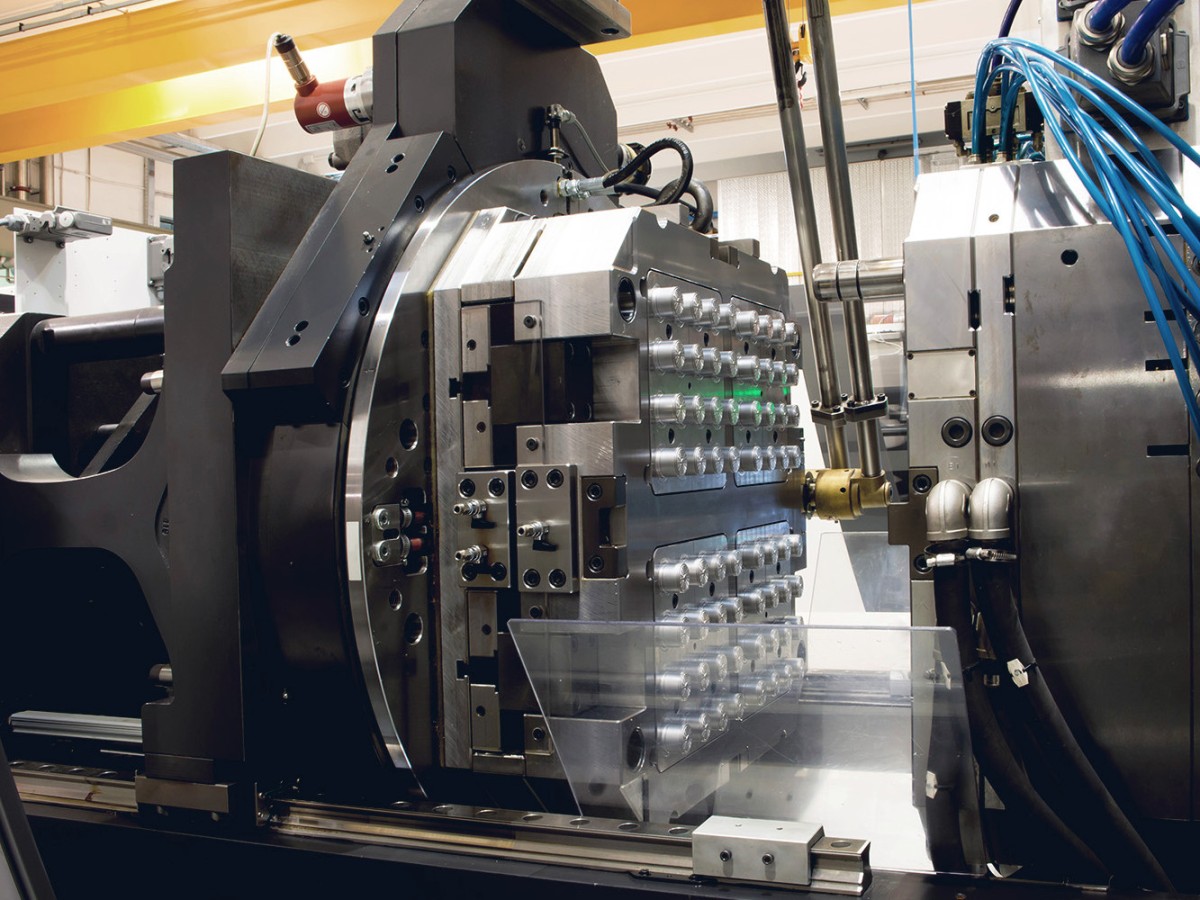

Various processes are used to shape plastics into the desired form. The machines and systems used are exposed to extreme loads.

Enormous forces of several hundred kilonewtons and temperatures in excess of 200 °C are at work. Special lubricants that are precisely tailored to the tribological requirements of the individual lubrication points are necessary to ensure that the machines and systems produce reliably over several years.

Tribological solutions for the lubrication of plastic injection molding machines

As a manufacturer, TUNAP provides a professional product range of release agents, lubricants, cleaners and surface protection products that can be used, for example, to achieve the highest possible number of shots in the plastic injection molding industry.

Higher production efficiency

The investment in high-quality lubricants makes up a comparatively small part of the maintenance budget of a plastic injection molding system. However, these lubricants can significantly increase the productivity of the entire plastic injection molding system.

The all-rounder: TUNGREASE CP-2/200

The fully synthetic TUNGREASE CP-2/200 is particularly noteworthy as a universally applicable lubricating grease.

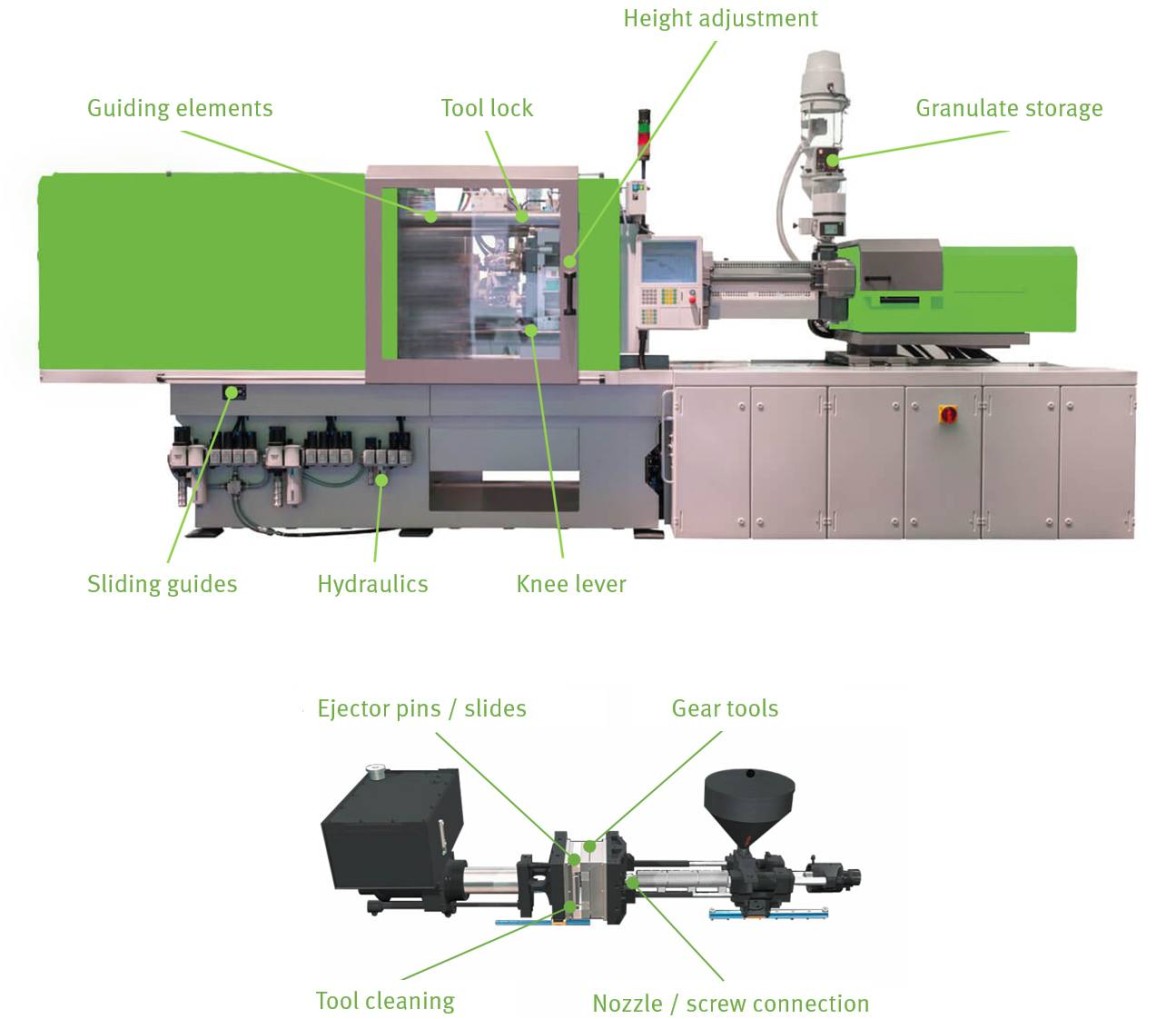

Wherever high loads occur, such as in toggle levers, on sliding guides or on guide elements, the extremely good surface protection comes into play and ensures extended component service life.

In addition, lubricant consumption is reduced as the long-term effect enables longer relubrication intervals.

The classic: TUNGREASE SG

TUNGREASE SG is the classic in our portfolio for plastic injection molding. The components are of extremely high quality and it is highly pure.

A small amount of TUNGREASE SG is sufficient to reliably lubricate the precise tolerances of ejector pins and sliders without being rubbed off.

Injection molded parts are not soiled or contaminated. It is also extremely temperature and evaporation stable, compatible with all plastics and has a very outstanding long-term lubricating effect.

Focus on maintenance and training

In addition to choosing the right lubricant, it is also important to adapt internal processes accordingly, for example through expert maintenance.

Regular staff training is key here, for example with regard to extending the lubricant change intervals for plastic injection molding systems.

Prioritizing lubrication

Injection molding systems in the plastics industry are expected to deliver top performance under extreme pressure, fluctuating temperatures and under the most adverse conditions. Product formulations with highly optimized protection and stability properties are the first choice for such lubricant requirements.

Prioritizing lubrication as part of a systematic maintenance strategy reduces the total cost of ownership, for example through shorter start-up times, lower energy consumption and optimized cycle times.

Certificates and NSF

With ISO 21469, TUNAP demonstrably fulfills the most comprehensive hygiene requirements for the production of H1 lubricants. The international certification is the most demanding proof of safety, reliability and product responsibility. The standard requires a holistic view of the life cycle of an NSF H1 product. Strict regulation of the formulation, ingredients, manufacture, handling, packaging, storage and use ensures the highest quality.