Products and Customers

Crystal formation in the SCR system? Workshops rely on TUNAP 987 for preventive system maintenance

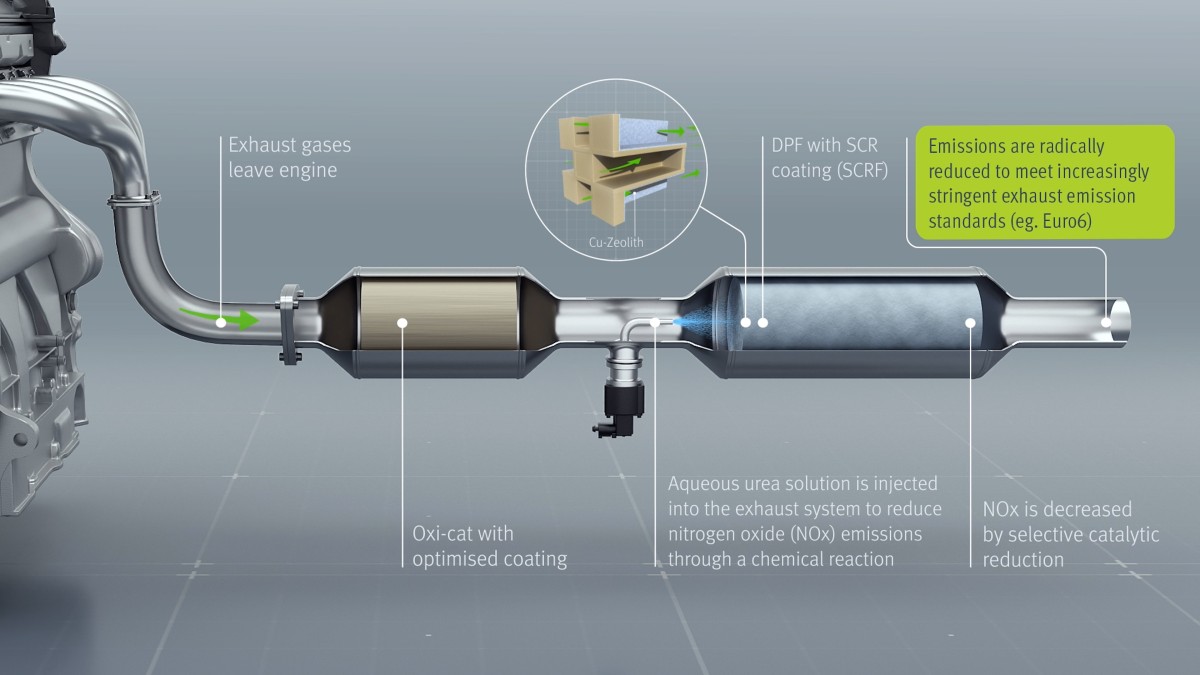

SCR catalytic converters have become an indispensable part of modern diesel vehicles. However, these systems are susceptible to malfunctions, particularly due to urea crystal formation. This can lead to malfunctions, increased pollutant emissions, loss of performance and engine problems, which can result in costly repairs.

Watch the video now:

With microflex® 987 System Active Ingredient SCR, TUNAP offers a tried-and-tested solution for reliably protecting urea dosing systems and SCR catalysts against crystal formation – while generating attractive after-sales revenue at the same time.

The challenge: crystal formation in the urea dosing system

A familiar problem often arises in workshop practice:

- The high temperatures required for complete conversion of the urea are often not reached in everyday operation.

- Insufficiently converted urea crystallises – especially in the dosing unit and in the SCR catalytic converter itself.

- This results in deposits that limit NOx reduction.

- The result: increased pollutant emissions, engine malfunctions, loss of performance and frequent visits to the workshop.

- This affects not only passenger cars, but also commercial vehicles, stationary units and stationary diesel systems with only short operating times.

The solution for workshops: microflex® 987 SCR system additive from TUNAP

TUNAP microflex® 987 was specially developed for preventive use in SCR catalytic converter systems. The patent-pending formulation reliably protects urea dosing systems and SCR catalytic converters from crystal deposits – without compromising the standard compliance of the urea solution.

Technical advantages at a glance:

✅ Effectively cleans dosing modules and SCR catalysts

✅ Prevents the formation of crystalline deposits

✅ No foaming when added to urea solution

✅ Compatible with ISO 22241 – SGS tested

✅ APL tested and suitable for compressed air-assisted systems

Application: Simple, safe, efficient

Handling is tailored to everyday workshop use:

- Dosage: 1:400 – 250 ml for 100 litres of urea solution

- Simple mixture: Add the active ingredient directly to the canister containing the urea solution

- Application: Add the urea solution as usual via the urea tank

- Recommendation: Use regularly with every refill

During service consultations in particular, recommendations offer additional benefits for customers – with genuine added value and minimal effort required to explain them.

Economic added value for the workshop

Workshops that regularly use TUNAP 987 report:

- Fewer complaints about SCR systems

- Sustainable customer satisfaction through preventive problem solving

- Clear sales potential through simple after-sales marketing

- Strengthening workshop expertise in dealing with SCR technology

- Increasing customer satisfaction

The recommendation is particularly useful as an added benefit for customers during service consultations – offering genuine added value and requiring little explanation.

Conclusion: Technical problem – intelligent solution

microflex® 987 System Active Ingredient SCR effectively protects SCR systems from the consequences of incomplete urea conversion and offers workshops a powerful product for the professional servicing of exhaust aftertreatment systems.